- Company Profile

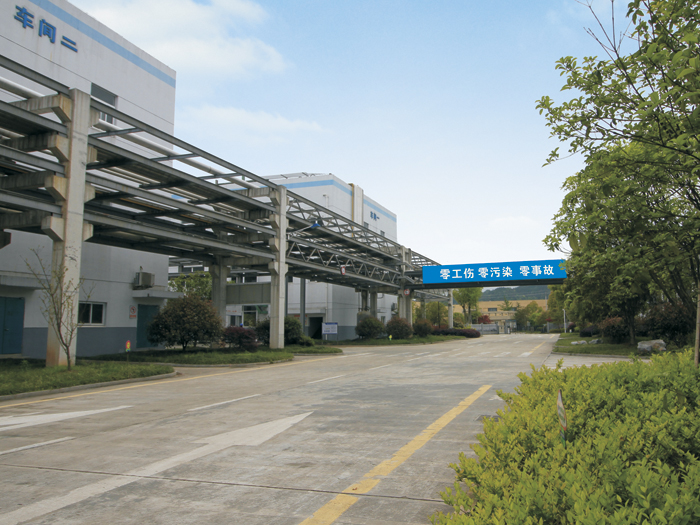

Jiande Jianye Resources Recycling Technology Co. Ltd is located at the Wumazhou district of Hangzhou Jiande High-tech Industrial Park. It was founded in year 2002. Jianye Resources has two major business fields including specialty organic amines manufacture and organic aqueous waste recovery.

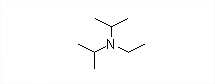

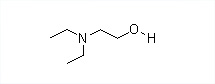

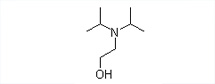

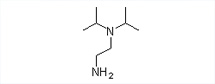

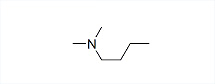

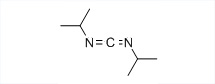

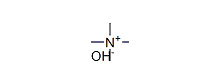

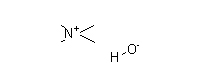

In the industry of specialty amines, Jianye Resources has an annually production capacity of 5000 tons. Jianye Resources developed the synthesis process of N,N-diisopropylethylamine, N,N-diethylethanolamine, N,N-diisopropylethanolamine, N,N-diisopropylethylenediamine and silicone catalyst of Tetramethylammonium hydroxide(TMAH) independently. Those products are competitive in the market with superior quality and good price.

Jianye Resources Recycling Technology is committed to becoming a global leader in specialty organic amines.